The Future of 3D Displays Comes into Focus

CAMBRIDGE, MA—3D displays for the unaided eye—depicted as holograms in movies—are notoriously difficult to get right. Viewers expecting to see deep, sharp imagery, and a field of view wide enough for several people at once, can be frustrated with blurred images, shallow 3D and a display screen that is big, clunky and expensive.

Draper engineers want to change all that by enabling truly holographic 3D video displays that improve the viewer experience while equipping display makers with leaner, smarter and easier-to-manufacture technology.

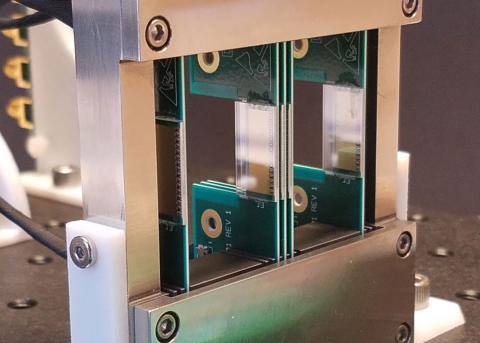

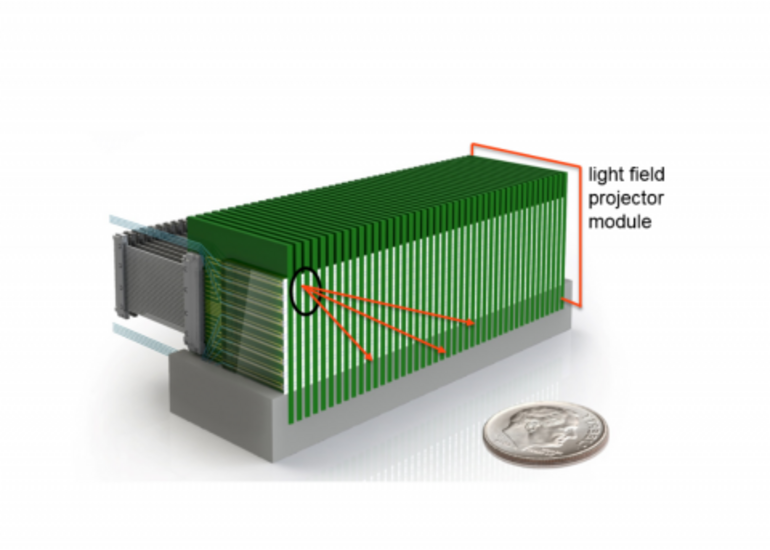

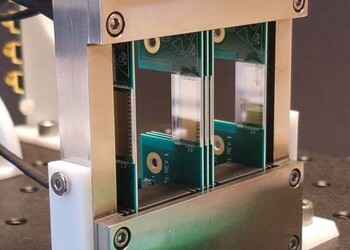

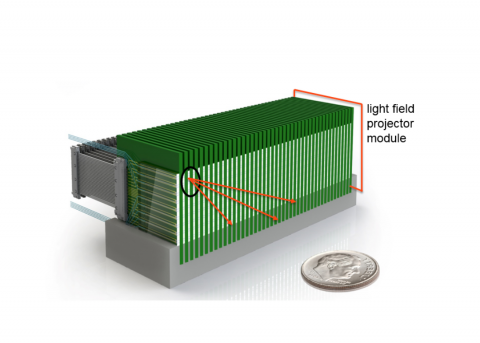

The new approach is possible because of technology miniaturization and novel methods for projecting light and integrating disparate technologies. Engineers at Draper did it by designing a light field projector module (LFPM) composed of surface acoustic wave (SAW) optical modulators mounted on a printed circuit board and illuminated with precise fiber-optic arrays. In one arrangement, LFPMs could be stacked to make an electroholographic light field projector that can give viewers a 3D image without glasses when it is integrated into a TV, computer or other display.

“Equipping a computer or TV display to create high-quality 3D imagery with a field of view wide enough for multiple observers and amenable to a thin package has been an open challenge in the display community for quite some time,” said Gregg Favalora, who designs 3D display technologies as a principal member of the technical staff at Draper. “Past attempts to make a scalable electroholographic display have too often resulted in displays with limited image size, narrow field of view, reliance on moving parts or impractical to reduce to a compact package. Only now is the technology advancing to a point where 3D systems can soon be deployed in complex, real-world environments.”

Those who care about 3D displays are growing. The military wants to use 3D terrain maps as a way to give soldiers better situational awareness about the world around them. Doctors want it for 3D medical imaging so they can see disease and injury more easily and perform surgery with higher precision. Consumers want it so they can be wowed by 3D images on TV and in theaters.

Draper’s modular LFPMs break new ground in compact, tile-able holographic video with the promise of depth and field of view. Recently, Draper engineers demonstrated millimeter-scale-thickness vertical modules that perform multi-beam light modulation with integrated fiber-optic illumination and no moving parts. In the next phase, Favalora and his team plan to take the LFPMs and array them horizontally into a display of holographic pixels, each of which utilizes acousto-optical electroholography to project numerous perspectives simultaneously. Where most typical autostereoscopic displays achieve a depth sensation by providing multiple perspectives at the expense of perceived resolution, electroholographic displays don’t have this trade-off—screen resolution and “view count” are decoupled.

Companies that design and manufacture 3D displays could see benefits, too, according to Favalora. “The LFPM technologies can be used in systems with the area of a postage stamp, or tiled into mobile, desktop or wall-sized holographic image projectors. That miniaturization is a boon for product companies that wrestle with reducing the size and weight of 3D displays,” Favalora said.

The work into 3D displays received investment from Draper as an internal research and development program. In developing the 3D display technology, the engineering team tapped into Draper’s expertise and facilities in photonics, micro-optics, microfabrication, system integration and subsystem maturity. These capabilities have helped numerous companies across industries solve engineering challenges to achieve the cost reductions, accelerated results, reduced risk and increased performance that they need to turn promising ideas into fielded capabilities.

Draper’s 3D display technology is currently being matured in advance of being licensed and integrated into future customer products.

Released January 15, 2019