Students, with Blimp, Take to the Air at Draper

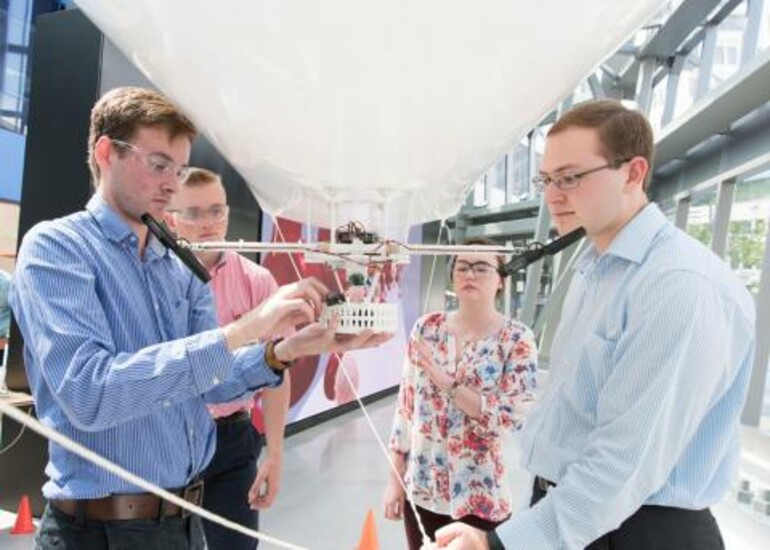

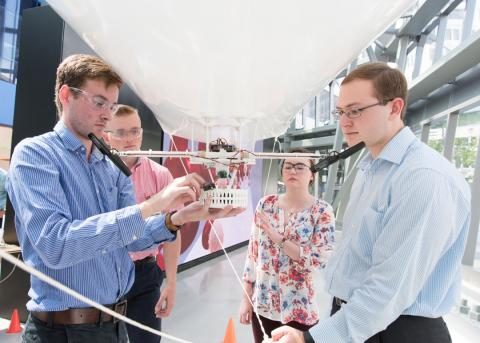

CAMBRIDGE, MA—A blimp guided by a cellphone app maneuvered to a drop spot and released a payload of sensors in a recent demonstration at Draper described by its inventors as “remote airship transporting.” The flight-and-delivery event took place at the culmination of a summer internship program involving eight students and two very impressed project advisors.

Valerie Bloomfield, an advisor on the project and a mechanical engineer by training, credits the students with working together to deliver the project on time and on budget, saying “even though we changed a few of the customer requirements midstream. Adjusting to those changes gave them real-world experience, and they did very well.”

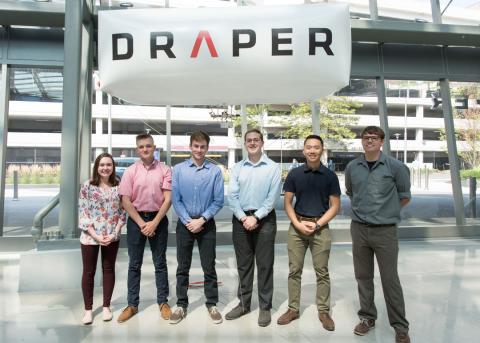

The team, named “Students Tasked with Remote Airship Transporting Utilities and Sensors,” or STRATUS, was co-located in Draper’s offices in Cambridge, Massachusetts, and St. Petersburg, Florida. The blimp project came with no instructions other than to design, build and fly it according to mission parameters, which was to develop a lighter-than-air vehicle capable of traversing hallways and open spaces to deploy sensors. The students demonstrated expertise ranging from design architecture, vision navigation, propulsion and deployment systems, to aerodynamics, hardware integration and development of a cellphone app for steering the blimp.

A common theme running through the students’ experience was that it gave them exposure to the project management at a large and complex engineering firm. Scott Young, a mechanical engineering student at Northeastern University responsible for hardware integration, said, “This is better than a classroom. To follow a project from brainstorming initial ideas to a final project was valuable.”

When the payload requirements changed, making the adjustment fell in large part to Aisling McEleney, a biomedical engineering student at the University of Massachusetts at Lowell. McEleney, who led the team’s efforts in sensor deployment and modular payload, said of the project, “I learned the importance of establishing a functioning minimal viable product on time and on budget before incorporating less crucial features, and the value of regular communication when working as part of a team split between two locations.”

Nate Robillard, a University of Maryland student in mechanical engineering and the point person for propulsion, agreed: “This is the first time I got a chance to work on a team with lots of different disciplines and talents and produce a final product. Having weekly meetings, budgets, time scheduling, PDRs [preliminary design reviews] and CDRs [critical design reviews]—we managed it all. At the end of the day it was up to us to get it to work.”

The other members of the team include George Gillespie, a student pursuing a combined bachelor’s and master’s degree in electrical engineering at the University of South Florida who was co-responsible for the project’s embedded systems and on task for cellphone app development and control systems; Paul Long, an electrical engineering student at the University of South Florida, co-responsible for the project’s control systems; Dalton Reith, a mechanical engineering student at Florida Polytechnic University who was on task for the aerodynamic characterization; Matthew Sanford, soon to enter Worcester Polytechnic Institute as a mechanical engineering student, was responsible for mechanical and electrical packaging; and Erik Shing, a mechanical engineering student at the University of Massachusetts at Lowell who was responsible for the design architecture. At Draper, Tim Dyer also served as a project advisor.

Last year, Draper’s summer interns designed and built a wall-climbing robot, and in 2016 they created a human-powered flying machine in the form of a dragon inspired by Game of Thrones.

Released August 21, 2018