Packaging Breakthrough Paves Way for PNT Systems for Harsh Environments

CAMBRIDGE, MA—The military’s reliance on assured positioning, navigation and timing (PNT) data is ubiquitous for a wide array of missions and platforms. PNT data are especially critical when GPS signals are unavailable. The optoelectronic devices embedded within many PNT devices, however, like the interferometric fiber-optic gyroscope, or IFOG, can benefit from new manufacturing methods in order to support applications in harsh environments.

Harsh environments tend to have large temperature swings and high amounts of shock and vibration. Such highly dynamic environments can cause performance issues for optoelectronics that were built using assembly and packaging methods developed for less dynamic environments.

A multidisciplinary team of engineers at Draper investigated the problem and developed new techniques in the way optoelectronics are packaged and assembled. Their breakthrough reduces the complexity, labor requirements and manufacturing costs for assembling and packaging optoelectronics, paving the way for their use in systems intended for harsh environments.

The new approach is an advance on the current assembly method that relies on robotic alignment and bonding of multiple optical components, along with individual miniature mounts, to a ceramic substrate, or bench. One limitation to this method is that it relies on adhesives to bond the components to the substrate—and adhesives tend to be gooey, sensitive to factors like temperature and humidity and difficult to dispense and manipulate at the microscale.

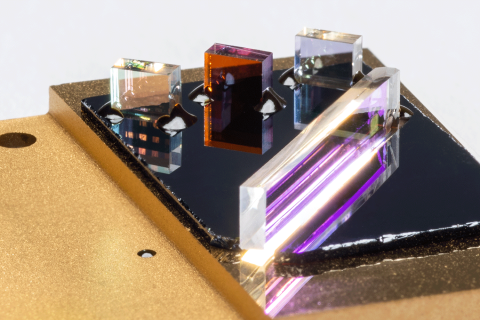

The Draper team leveraged the company’s in-house microfabrication facility to fabricate and optimize silicon optical benches, or SiOBs, which are wafer-level platforms composed of precision etched surface features that efficiently and directly locate and integrate many of the discrete components of an optical system without the need for additional miniature mounts. This approach uses a passive alignment method, which requires fewer steps than an active method for assembling the components.

Draper’s method enables multiple lenses and beam splitters to be dropped onto the etched silicon surface along with pieces of low-melting-temperature solid glass frit, prefabricated into 3-D shapes (such as rectangular blocks and circular doughnuts) that are designed to optimally register and anchor the optical components, and then simultaneously fused to the SiOBs in a single melt/cool step in a matter of minutes. This new process replaces the time-consuming and high cost-of-ownership combination of precision robotics and liquid adhesives where the grabbing, releasing and drifting of the optical components during adhesive curing is often problematic.

The new capability has proven to be a highly accurate way to assemble multiple microscale optical components extremely close together within a single device, according to Gilbert Feke, Draper’s technical director of the project.

“In this work, we focused on miniaturizing a solution for distributing light from a single diode to three orthogonal IFOG fiber coils by integrating optical components onto the SiOB platform, and matured the assembly and packaging capabilities to a level at which they could support both an in-house rapid prototyping paradigm and transfer to a manufacturer for production builds of hardware,” Feke says.

The new method is available to Draper’s customers to improve their IFOGs and other devices. Neil Patel, Draper’s task lead on the project, says, “The SiOB design toolkit and tolerancing rules we developed, along with the single-step self-alignment method, standardizes the design process, lowers the packaging cost and increases manufacturing scalability.”

The work was funded by Draper and its internal research and development program, a corporate investment which develops advanced capabilities that then can be brought to customers in the government, commercial sectors and R&D community.

Released March 29, 2022