Tackling the Wafer-level Solder Seal Challenge

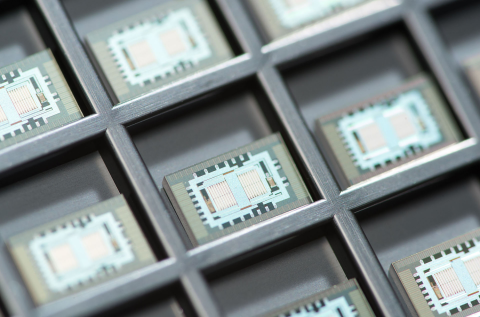

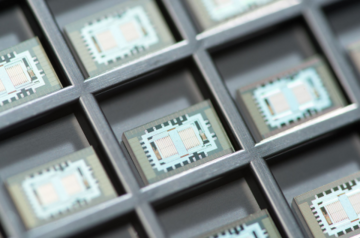

CAMBRIDGE, MA—Semiconductors are a key cog in the technological machine that makes our modern world go. These small components are becoming ever smaller and increasingly packed with a variety of subcomponents, requiring new manufacturing techniques.

Now, new guidelines for soldering and sealing large, heterogeneous assemblies at wafer level are showing promise for improving yield by optimizing seal design.

In a series of experiments, Draper engineers investigated the interplay between seal width, solder volume and the gap between seal surfaces. They focused on problems such as wafer bow and irregularities in the seal surfaces, and they compared solder that’s applied to flat surfaces and solder that bridges a gap between surfaces. Their models predicted the solder’s behavior in several settings, providing a decision-support tool for microelectronics manufacturers.

The findings were presented at the October 2022 IMAPS International Conference in Boston. “The guidelines can be used to compare solder surface areas of different geometries and select the one that minimizes the area the solder interfaces with the silicon,” said Tom Marinis, the paper’s co-author and a principal member of the Laboratory Technical Staff at Draper.

Future development of the capability will look into incorporating certain surface energies into the researchers’ models. Specifically, the plan is to differentiate between surface energies of free solder and wetted surfaces.

The IMAPS conference presentation and article, titled “Design of Wafer Level Solder Seals—A Surface Energy Perspective,” was written by Marinis and Joseph Soucy, a principal member of the Laboratory Technical Staff at Draper.

Draper develops microelectronics for energy, transportation, defense and cybersecurity, and excels at developing extremely small sensors with surprising sensitivity and resolution that are cost-effective and thus easier to distribute widely. Draper facilities in Cambridge include a microfabrication center, MEMS facility, polymer fabrication, precision machine shop and a Center for Additive Manufacturing.

Released January 12, 2023