Draper Awarded $14M by DoD for Trusted Advanced Packaging Capability Expansion with i3 Microsystems as Major Subcontractor

CAMBRIDGE, MA—Draper announced today it has been selected for two U.S. Department of Defense (DoD) contracts, totaling $14 million, to enhance the U.S.’s ability for volume production of advanced packaging solutions for computer chips embedded within defense systems. i3 Microsystems, Inc., of St. Petersburg, Fla., will be the major subcontractor for production.

Draper received a $10 million contract from the Defense Production Act (DPA) Title III Office, which represents a second phase of funding under this program for Draper and i3 Microsystems. The first phase was awarded in 2018. Draper also received a $4 million contract from the U.S. Department of Defense’s Industrial Base Analysis and Sustainment (IBAS) office.

Access to secure state-of-the-art microelectronics used by military systems like DoD aircraft, ground vehicles and complex weapons systems is critical to ensuring our nation’s technological advantage. Draper’s packaging technology has proven itself an effective high-density and protective solution that leverages the commercial processing ecosystem to enable adoption of heterogeneous technology for mission success.

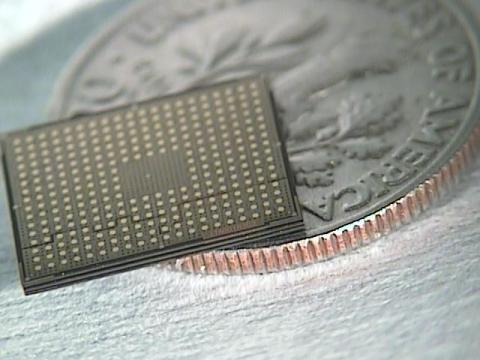

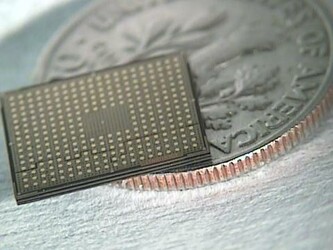

The goal of the awards is to expand existing domestic supplier production capabilities to produce three dimensional (3D), ultra-high-density microelectronics modules for use in mission critical applications. The companies will focus on product yield improvement and the expansion of production facilities to create a sustainable DoD supplier of 3D microelectronics modules addressing specialized processing needs through heterogeneous integration.

Draper’s team for this effort includes i3 Microsystems, a U.S.-owned company, to manufacture multi-chip modules (MCMs) at their volume, Defense Microelectronics Activity (DMEA)-certified, trusted foundry manufacturing center where i3 Microsystems uses fan-out wafer level packaging (FO-WLP) technologies to produce a wide range of high complexity electronic assemblies. i3 Microsystems offers one-stop vertically integrated services for the manufacturing of these type of advanced electronics.

“Draper and i3 are addressing two critical challenges in the global supply chain: the design and production of densely packaged semiconductors for a variety of DoD applications. We believe this program will strengthen supply chain resiliency, and the defense industrial base of the United States, and provide added protections for microelectronics designed for defense systems, especially against adversaries, including those engaged in the Great Power Competition,” said Neil Adams, vice president of national security and space at Draper.

“We look forward to continuing to work with Draper to deliver these complex products to the DoD user community at ever-improving yields and commercially competitive prices,” said Justin Borski, director, programs and business development at i3 Microsystems.

Draper’s heritage of packaging innovation is built on a foundation of secured and assured systems. All of its high-density products are designed and manufactured in DMEA trusted facility environments in the U.S. The company’s defense microelectronics expertise includes development of new technologies to safeguard the U.S. military electronics supply chain from substandard, used and counterfeit electronics.

i3 Microsystems

i3 Microsystems, Inc. (i3M), with corporate headquarters in Binghamton, NY, is a vertically integrated provider of high performance electronic solutions consisting of design and fabrication of fan-out wafer lever packages and advanced semiconductor packaging, with full turnkey services for electronic assemblies and integrated circuit assembly and test, cable and harness manufacturing, and world class PCB reliability and failure analysis test laboratories. www.i3microsystems.com

Released March 30, 2021