Wood Grown in a Lab Could Reduce Deforestation, Lead to Furniture Made from Plant Cells

CAMBRIDGE, MA—In a natural setting, wood production is a slow process. Even fast-growing trees may take as long as 20 years to acquire a profitable volume of timber. To reach that volume, a large portion of a tree’s available resources and energy have been expended producing industrially unworkable materials such as leaves, bark and small limbs.

What if wood could be grown in a lab? That’s the question at the center of a new study detailing how to create lab-grown wood indoors without soil or sunlight. The study proposes a new approach to plant-based biomaterial production that substantially lessens or altogether eliminates inefficiencies in the agricultural and pre-processing stages.

Ashley Beckwith and her fellow researchers describe the process of growing the wood-like plant in a paper recently published in the Journal of Cleaner Production.

“We have this increasing demand for products and foodstuff as the population continues to grow,” Beckwith, a Draper Fellow and Ph.D. candidate at MIT, told Digital Trends. “We need to start finding alternative and more strategic ways to produce these plant-based materials.”

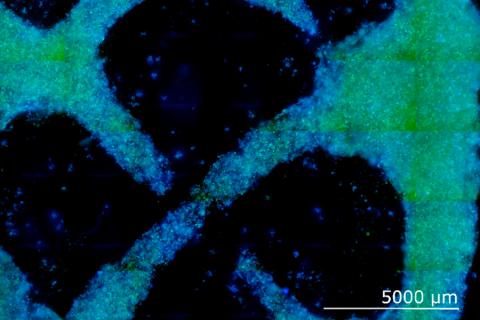

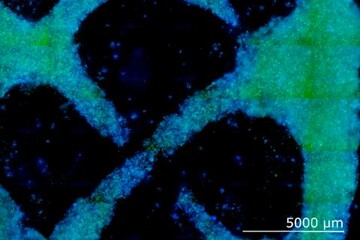

The researchers describe in their paper how plant cell development can be controlled by adjusting local environmental conditions and that the scalable, land-free cultivation of plant material like wood for use in furniture making, for example, one day may be possible. The team printed tiny, proof-of-concept material samples in Petri dishes, currently using the zinnia plant, a genus of plants within the daisy family.

“Despite considerable and early resource investment (imagine the cost of buying, fueling, and operating logging trucks and roads alone), only a small fraction of the cultivated crop may be economically valuable at harvest,” write the authors in their paper, noting also that for the production of some natural fibers, as little as 2% to 4% of the harvested plant matter will be used.

Coauthors are Beckwith’s co-advisors Luis Velásquez-García, a principal scientist in MIT’s Microsystems Technology Laboratories, and Jeffrey Borenstein, a biomedical engineer at Draper.

Borenstein says it’s a convergence of engineering and biology in ways that people could only imagine just a few years ago. “There’s an opportunity here to take advances in microfabrication and additive manufacturing technologies, and apply them to solve some really significant problems in the agriculture arena,” he explained in an interview with MIT News.

The research builds on Draper’s work in biomedical solutions demonstrated in human organ systems, biomimetics and microfluidics.

Released February 16, 2021